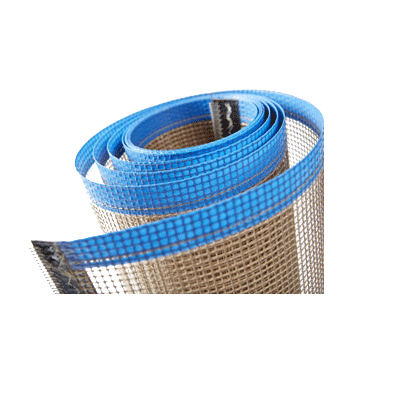

Mesh belts are produced from many different materials on special order. The purpose of mesh lining is to control air, water or other materials / radiation through the surface of the tbelt. Used for ventilating, flushing and vacuuming various materials.

Types:

- Teflon Mesh Tapes – Used in Printing Machines, UV Dryers and Food Industries. Composed of endless tape made of Teflon fabric. More than thirty addition methods are used depending on the need. The advantages are good temperature resistance up to 240 ° C, and the details do not stick to the material

- Plastic gauze /mesh belts – Used in the food industry, the task of tapes is to flush out or wash off unnecessary substances. Grid linings are made of various plastics and metals. The joining methods are braiding and stitching.

- Metal mesh belts – use in different industries for ovens, good temperature resistance and durability according to metal type. Different types of fabrications possible.

- Hybrid mesh belts – are made by interlacing metal and plastic under special conditions in which the conveyor operates.

- Spirals belts